| Machining Process | Brass Forging and Machining, Precision Machining and Large Machining, Investment Casting of Lost Wax, Pressure Die |

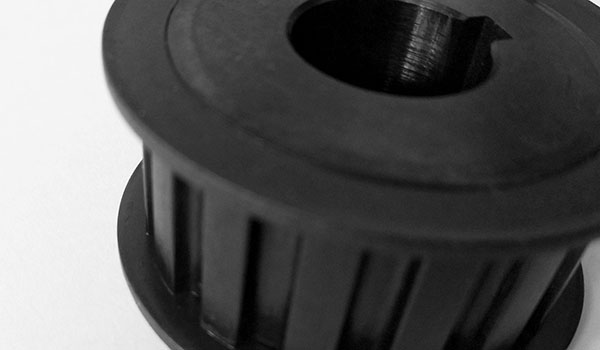

| Surface treatment | Black Oxide, anodic oxidation |

| Material | Steel, Carbon Steel, Stainless Steel, Aluminum, Copper, G25, G3000, Plastic, Nylon |

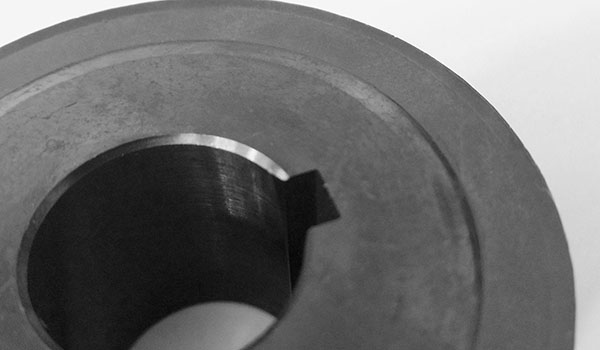

| Bore Type | Pilot bore, Taper bore and Customized bore |

| Teeth number | 18, 20, 22, 24, 26, 28, 30, 32, 34, 36, 38, 40, 42, 44, 46, 48, 50, 52, 54, 56, 58, 60, 64, 72. |

| Surface treatment | Anodized, Black Oxide, Galvanized, Phospharing |

| Feature | Oil-Resistant, Corrosion-Resistant, Heat-Resistant, Wear-Resistant, Acid-Resistant, High Temperature-Resistance |

| Application | Our products are widely used in many industries, such as agricultural machinery, mining machinery, petroleum machinery, textile machinery, conveyer equipment, packaging machinery, food machinery, engineering machinery, fitness equipment, automobile, truck, train, railway, and other power equipment.- Mechanical Components/parts Boat parts and Marine hardware Construction hardware Auto parts and accessories Medical Instrument parts pump & valve parts and accessories Pipe Fittings or pipeline accessories Other industry metal casting parts |

| Design | Pro/E, Auto CAD, Solid work, CAXA UG, CAM, CAE.Various type of 2D or 3D drawings are acceptable,such as JPG, PDF, DWG, DXF, IGS, STP, X_T, SLDPRT etc. |

| Standards | AISI, ATSM, UNI, BS, DIN, JIS, GB etc.Or Non standard customization. |

| Inspection | 100% inspection on critical dimensions or follow your special requst. |

| Certification | ISO9001:2015 quality management system certificate.( Continuous update ) |

| Equipment | Hobbing machine, Drilling machine, CNC machine, Milling machine, Gear shaper, Grinder etc. |